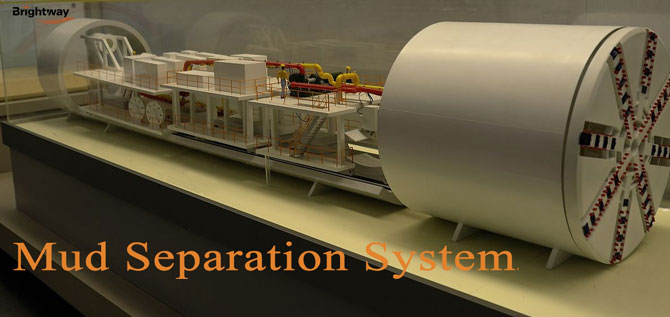

Brightway Mud Separation System in Shield Tunnel

Shield tunnel construction technology is the cutting-edge technology of trenchless technology. Shield tunnel is one of the underground construction method with fully mechanized construction. During the construction, shield shell and segment are very important bearing to prevent tunneling collapse. At the same time, the cutting device for soil excavation will be in front of the excavated surface. And the earth will be transport out of the tunnel by machine. The processing will be pressurized into by lifting jack, with assembling precast concrete segment. Thus, it forms a kind of mechanical construction method of tunnel structure. Mud recycling is implemented by the mud conveying system in the shield construction. The waste sand from shield excavation will be shifted into cutting positions. Meanwhile, the high-density slurry from mud pump mixing will be shifted to the mud separation system for recycling after mud processing.

Mud separation plant in the domain of shield construction is an important guarantee for shield machine excavation normally. Mud separation plant must be safe and absolutely reliable in the shield tunnel construction.

Mud separation system is divided into two parts. The first part is the mud separation and processing system, and the second part is the cyclone separation system.

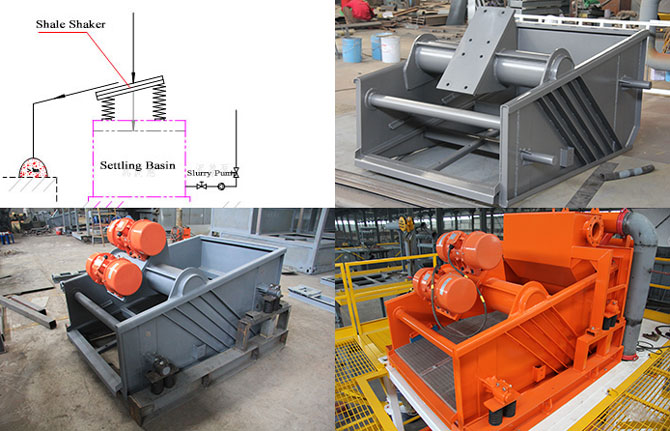

♦ Mud Separation and Processing System

The function of mud separating system is to processing the mud from shield cutting soil sand formation, and recycling slurry back into slot. Shale shaker as the primary separation is more appropriate. Shale shaker plays a role to pretreat the mud, removing clumps and block the big particles etc. Coarse particle separation need to use multilayer shale shaker to meet particle classification. In order to meet the requirements of the use of the mud particles, different sizes of particles are through the sieve mesh screen processing. In this processing, bigger particulate matteris is sieved out of the system, and meshed mud flows into the sedimentation tank.

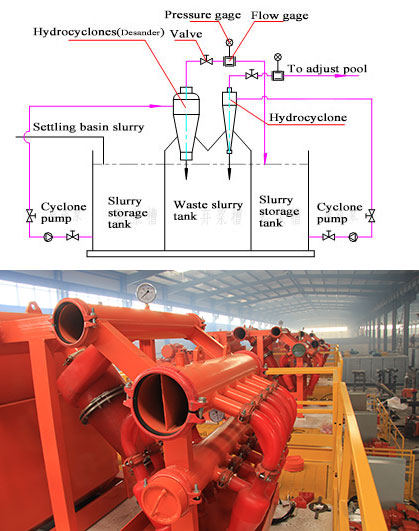

♦ Cyclone Separation System

Cyclone separation system mainly consists of two parts, sand cleaning and desilt. The main function of brightway cyclone separation system is to refine the slurry sieved by shale shaker, and successively reduce slurry particle size, to achieve the hydrocyclone separation and solid control. The working principle of cyclone is based on high-speed centrifugal force by hydrodynamic processing to achieve. By using vortex pump in spinning process to produce negative pressure, so that tiny particles suspensed in the hydrocyclone are extruded spirally through the overflow outlet by negative pressure. And heavy particles in slurry under the weight of gravity fall into the underflow outlet of the pulp groove. Different diameter and neck length ratio of cyclone determine the cyclone processing effect and processing capacity with different working pressure.

◊ Shale Shaker in Mud Separating System

Shale shaker as the primary separation is more appropriate. Shale shaker plays a role to pretreat the mud, remove clumps and block, big particles etc.

√ Brightway shale shaker uses the ANSYS finite element analysis and the optimized structure design. It is produced to maximumly meet ergonomic design operation.

√ Brightway shale shaker is adopted the industry leading pickling, passivation, hot galvanizing technology. The lifetime of brightway shale shaker is greatly improved.

√ Brightway shale shaker takes Martin or Oli brand vibration motor.

√ Brightway shale shaker selects Siemens, schneider, ABB and other international well-known brands electrical components.

√ Brightway supplies and designs different mud separation system according to the different factical separation requirement.

◊ Vortex Hydrocyclone in Processing System

Cyclone separation system mainly consists of two parts, sand cleaning and desilt. The main function of brightway cyclone separation system is to refine  the slurry sieved by shale shaker, and successively reduce slurry particle size, to achieve the hydrocyclone separation and solid control.

the slurry sieved by shale shaker, and successively reduce slurry particle size, to achieve the hydrocyclone separation and solid control.

The working principle of cyclone is based on high-speed centrifugal force by hydrodynamic processing to achieve. By using vortex pump in spinning process to produce negative pressure, so that tiny particles suspensed in the hydrocyclone are extruded spirally through the overflow outlet by negative pressure. And heavy particles in slurry under the weight of gravity fall into the underflow outlet of the pulp groove. Different diameter and neck length ratio of cyclone determine the cyclone processing effect and processing capacity with different working pressure.

√ Brightway cyclone separation system has more reasonable structure and lower power loss.

√ Brightway hydrocyclone for sand cleaning and desilt are adopted high abrasion resistance composite pu material.

√ Brightway mud separation equipment is adopted pickling and passivation, hot galvanizing technology.

√ Brightway shale shaker screen is easy to maintain and can be interchangeable with international brand.

Shield tunnel field information

Shield tunnel construction has been used for more than 170 years. with the continuous improvement of scientific level, shield tunnel technology has been developing and perfecting. So far, shield tunneling has become a special tunnel construction machinery of the soft soil layer construction. Shield tunnel construction method has become indispensable in nowadays’ urban tunnel and underground engineering construction method.

More about Brightway solids control system and mud recycling equipment goes to tunneling mud separation system.