The biggest argument FOR these machines seems to be offshore where environmentally there have been few choices available historically to deal with cuttings:Vertical Cuttings Dryers. Better shale shakers and screen management are key to reduce drilling fluids contamination of LGS from the repeated degradation of cuttings from Solids Control Equipment. The issue onshore or offshore is that not every rig has top of the line shale shakers. The “new kids on the bloc” which are neither shaker nor dryer have huge price tags per unit. They vacuum fluids off the cuttings to the point that there are apparently no issue with discharge of the cuttings overboard as they supposedly are within discharge spec…<6.9% for SBM.

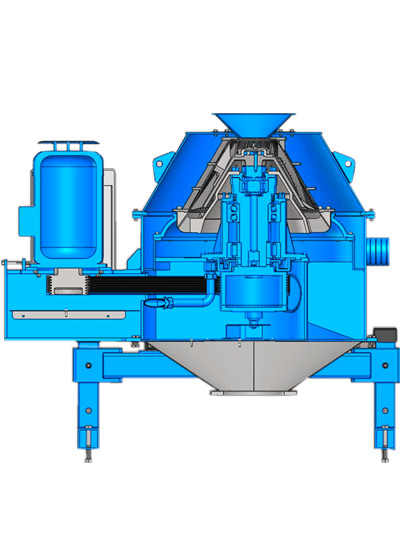

Here is the solution of drilling waste :Vertical Cuttings Dryers

I am sure that we can all agree the shale shaker is your 1st line of defense at solids control. You must have the best you can possibly purchase. There are some good machines on the market and there are some really great ones…all at a cost. The question then becomes what do you do with that discharged solid waste?

I have experience with a very good thermal unit. Our product return to the drillers was so good, according to them, that they often visited our unit to watch the process.

By no means is thermal the answer to all problems. It is costly environmentally when the process is broken down into segments.. Energy consumption is horrendous per meter cube processed.

CRI or re-injection of those solids back into formation….there are some who will NOT sign off on that.

Burial is another option in some locations, illegal in many locations

There are acres of solids in holding pits in the USA because they still do not know what they want to do with them-so I am told

Land farming, just loads of different ways. None are great for all situations. Centrifuging will not totally complete the problem either. I have been brow beat over “why does solids control always offer those machines which dirty up our mud?”

The answer I see is because we always engineer backwards. We sell terrific muds and chemicals but often times don’t worry about clean-up of wastes. Let’s design a program from the trash can back to spud once in a while. The mud company that does that has the answer….I know of one such company that has developed a mud that at midnight twinkles and turns back into a pumpkin very expensive at the moment but they seem to be happy with it for now.