Hydrocyclone Desander

Brightway is the professional Hydrocyclone Desander manufacturer and Desander supplier in China. and can manufacture Hydrocyclone Desander with the sizes of 8″, 10″, 12″ and 14″ for oil drilling mud system and 14″~20″ Hydrocyclone for Desanders for micro-tunneling...

WhatsApp

Email

Solids Control Equipment

Desanders are solid controls equipment with a set of hydrocyclones that separate sand and silt from the drilling fluids in drilling rigs. so it is called Hydrocyclone Desander or Desander Unit. Desanders are installed on top of the mud tank following the shale shaker and the degasser, but before the desilter. Desander removes the abrasive solids from the drilling fluids which cannot be removed by shakers. Normally the solids diameter for desander to be separated would be 45~74μm.

Brightway is the professional Hydrocyclone Desander manufacturer and exporter in China. we can manufacture Hydrocyclone with the sizes of 8″, 10″, 12″ and 14″ for Desander for oil drilling mud system and 14″~20″ Hydrocyclone for Desanders for micro-tunneling separation plant. And Cyclone Desanders and Desanders without bottom shaker in different capacities can also be provided.

BWCSQ series Desander Features and Benefits

1. Design: Adopt ANSYS limited element analysis to optimize the structure.

2. Material: Use Q235B from BAOSTEEL for body, and High strength compound rubber material used to reduce shock.

3. Vibration motor: Italy OLI /American Martin, or according to customer requirement.

4. Electrical control system: Explosion-proof electrical control system with electrical components as ABB, Siemens, Schneider

5. Treatment: Grinding, Abrasive blasting, Epoxy zinc rich primer, Intermediate painting with epoxy micaceous iron, and Finish painting with polyurethane

6. Hydracyclone cone: Made of wearing-resist polyurethane and in the structure similar to Derrick design.

7. Inlet and outlet: Fast joint connection

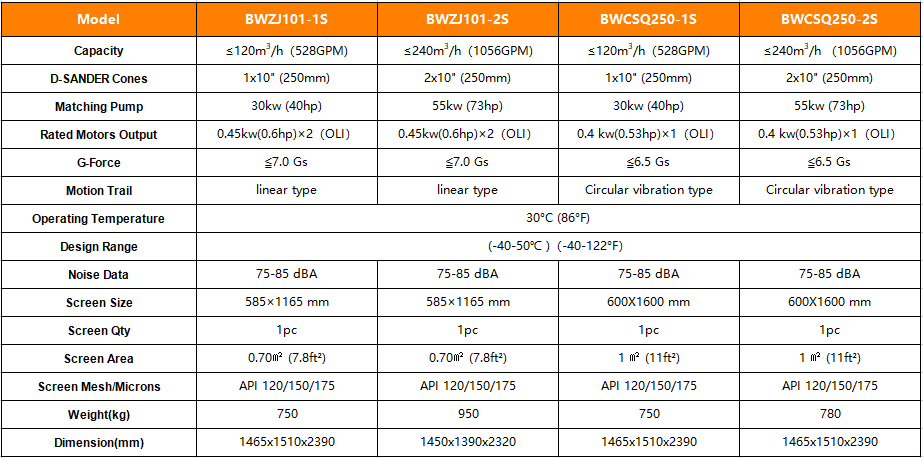

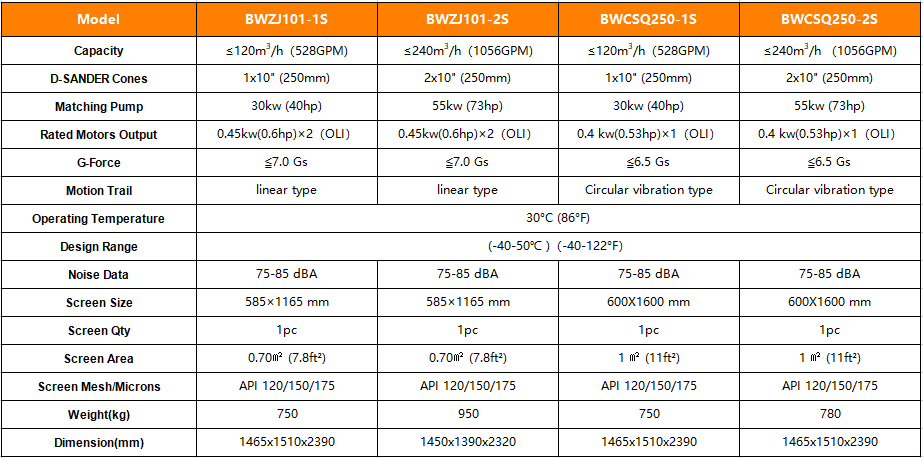

BWCSQ series Desander Parameters

Power: 220-240V/ 50Hz, 380-415V/ 50Hz, 440-480V/ 60Hz, 575-600V/ 60Hz

Certification: IEC/UL/ATEX/CE

Remark:

1. Shaker motor type selection can be configured according to customer requirements, explosion-proof and non-explosion-proof can be selected according to industry requirements;

2. The matching shaker and cyclone can be selected according to the purchasing power of customers;

3. Shaker screen can be selected according to customer requirements, iron frame, composite material or plate wave screen;

4. The treatment capacity of the above equipment is measured in mud density: 1.2g /cm3, mud viscosity :45s, screen mesh: 40 mesh;

Please Leave Your Request

If you haven’t found useful information about “Desander” from this page, please fill below table for detailed inquiry.

or send the request to our Company Email: brightway@bwwell.com we will feedback at the soonest!