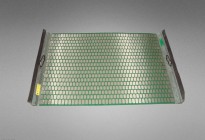

Brightway BWD500/2000 series corrugated Shaker Screens can be used in the 500/2000 shale shakers. The shaker screens dimension is 697x1050mm and can be used in 1050mm box of ZS series shale shaker for drilling mud system. such as 500 series shale shakers and 2000 series shale shaker.

Brightway BWD500/2000 Corrugated Shaker Screen has typical mesh cloth that appears regular waves,and it can be mounted on suitable shaker by hookstripe,or wedge-shaped fastening device. As compared to flat screens,Corrugated Shaker Screen have higher handling capacity by reason of more useful area.we can provide various sizes of Corrugated Shaker Screens to serve the clients’demands.

As the Corrugated Shaker Screen Manufacturer, Brightway BWD500/2000 series corrugated Shaker Screens have been exported to more than 40 countries. such as: Singapore, Indonesia, Malaysia, Thailand, Philippines, India, Pakistan, UAE, Saudi Arabia, Qatar, Dubai, Iran, Iraq, Egypt, Russia etc.

Brightway Corrugated Shaker Screen Model

D-500 Corrugated Shaker Screen

Mesh: 20-300

Dimension: 697x1050mm

Weight: 7.5/6.0kgs

Screen Material: S.S304

Frame Material: Carbon steel

D-2000 Corrugated Shaker Screen

Mesh: 20-320

Dimension: 697x1053mm

Weight: 5.8/4.2kgs

Screen Material: S.S304

Frame Material: Carbon steel

Brightway Corrugated Shaker Screen Features & Benefits

Screen Finer Faster – Utilizing Corrugated Shaker Screens enables rigs to screen 2 to 3 mesh sizes finer than with traditional flat panel screens without sacrificing capacity. This maximizes solids removal capabilities.

Makes Fine Separations – Corrugated Shaker Screens are capable of making separations as fine as 43 microns.

Fits Existing Shakers – There is no need to modify or replace existing equipment. Corrugated Shaker Screens fit all shakers, allowing the most efficient use of existing equipment.

Drier Cuttings – Corrugated Shaker Screens minimize fluid loss by spreading thinner layers of fluid over a relatively larger screen surface, offering more effective drying results.

Enhanced Permeability – Gravity and vibration forces the solids into the corrugated screen’s troughs, thus allowing more fluid to pass through the top of the screen.

Please Leave Your Request

If you haven’t found useful information about “shale shaker screen” from this page, please fill below table for detailed inquiry.

or send ?the request to our Company Email: brightway@bwwell.com we will feedback at the soonest!