Vertical Cuttings Dryer

Vertical cuttings dryer could be regarded as a vertical centrifuge, and widely used to treat drilling cuttings in oil drilling field. Drill cuttings dryer is the core equipment of drilling cuttings management. it can be to reduce waste and increase fluid recovery. Brightway’s rugged, continuous...

WhatsApp

Email

Solids Control Equipment

Vertical cuttings dryer could be regarded as a vertical centrifuge, and widely used to treat drilling cuttings in oil drilling field. Drill cuttings dryer is the core equipment of drilling cuttings management. it can be to reduce waste and increase fluid recovery.

Brightway’s rugged, continuous Vertical Cuttings Dryer is fed via screw conveyor, vacuum system, or rotary-lobe solids pump from the flow-line shale shakers. Drill cuttings are fed into the jet mud hopper(hopper), and distributed along the inner wall of the screen with the aid of the rotor.

Brightway is the good Cuttings Dryer Manufacturer in China and the the first one to bring in synthetical analysis technology and patent from Italy, as well as apply this technology to vertical cuttings dryer. Brightway’s vertical cuttings dryer copes with oil-based and water-based problem in native country and foreign countries, which is also applied to maximally meet the demand for drilling waste processing on different working conditions. By using this equipment, oil-based drilling mud can get the same processing result with water-based drilling mud, which can 98% satisfied customers.

Vertical Cuttings Dryer Features

1. Adopting Italy comprehensive analysis technology to meet domestic and overseas customers `s treatment requirments on the drilling site

2.The Capacity can be up to 50 tons.

3. It can separate and dry different kinds of drilling waste, such as water-based mud, oil-based mud, composite mud.

4. Adopting independent oil lubrication and cooling system to extend equipments lifetime.

5.The discharge port is flexible to operate, which can be in different types, such as spiral type, belt type.

6. Water-based mud and composite mud: Water content 8-10%, oil-based mud: water content≤6%, OOC≤3%.

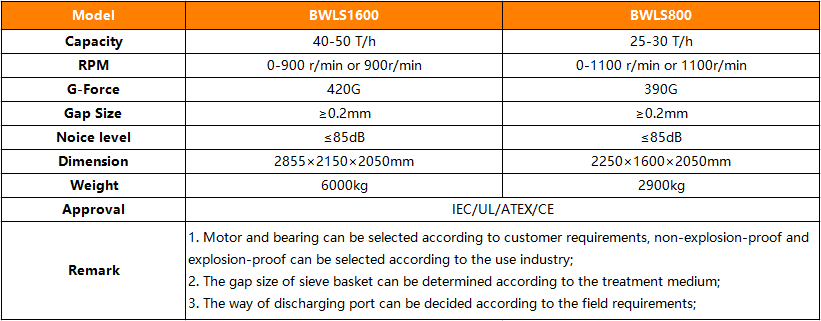

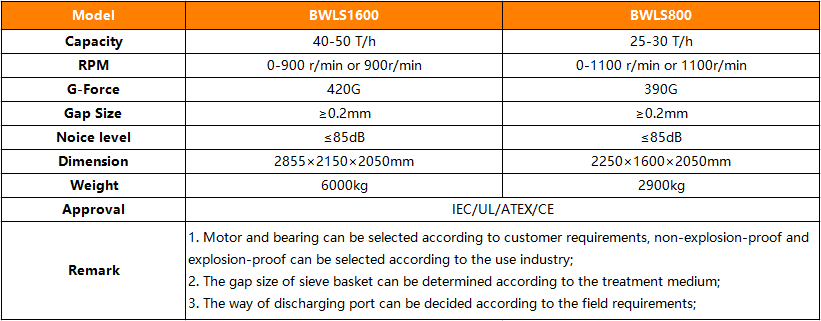

Brightway Vertical Cuttings Dryer Parameter

Please Leave Your Request

If you haven’t found useful information about “Cuttings Dryer” from this page, please fill below table for detailed inquiry or send the request to our Company Email: brightway@bwwell.com. we will feedback at the soonest!