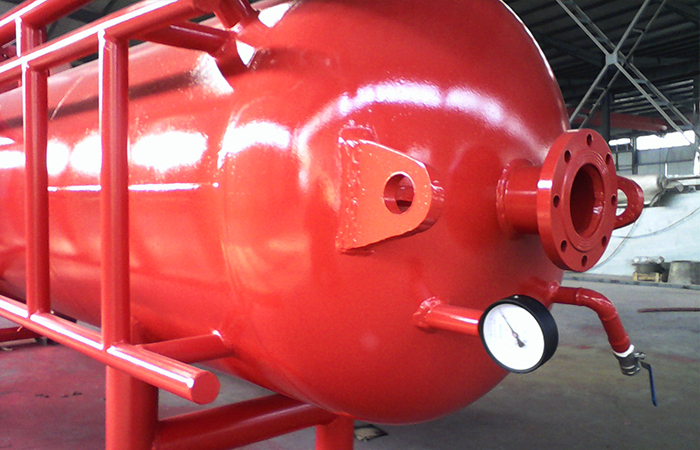

The mud gas separator is a commonly used important equipment for processing drilling fluid gas intrusion in the oil drilling process and a special equipment for primary degassing of gas-invaded drilling fluid. What are the specific installation requirements for gas liquid separators? The mud gas separator separates and discharges a large amount of free gas and toxic gas in the mud, and then discharges the gas to the safe area of the well site through the blow-out pipeline for combustion treatment. This process is highly dangerous, so the mud gas separator is installed The requirements should pay attention to the following aspects.

Installation requirements for mud gas separator:

1) Ground requirements for installation of mud gas separator:

Under normal circumstances, the ground required to install the mud gas separator is level and has a reserved position for the anchor bolt pit.

2) Installation and lifting requirements for mud gas separator:

Under normal circumstances, the first requirement for the installation and lifting of the mud gas separator is to use a crane to lift the lifting lugs on the top of the mud gas separator and keep it vertical to the ground. After putting it down carefully and slowly, use a steel wire rope to tighten and straighten the mud gas separator from the upper part of the gas liquid separator and the horizontal ground to ensure that the mud gas separator is vertical to the ground, and pour ground bolts and tighten them.

3) Requirements during installation and transportation of mud gas separator:

Under normal circumstances, the pipe manifold needs to be removed during installation and transportation of the mud gas separator, loosen the tight wire rope, and lift the top of the gas liquid separator with a crane to ensure that the anchor bolts are level and loosen it.

4) Operation requirements after the mud gas separator is installed in place:

After installing the mud gas separator in place, lead the exhaust pipeline to a distance of 60-80m from the wellhead. Connect the slurry inlet with the rotary blowout preventer or the throttle pipe, close the sewage butterfly valve and open the slurry outlet butterfly valve, and then connect the pipeline to the inside of the mud tank to start the formal work.

The combined use of drilling mud gas separator and electronic ignition device can ensure the smooth progress of the drilling process.

The mud gas separator designed and produced by Brightway can achieve the circulation effect of drilling fluid by removing a large amount of gas. Its design principle meets the requirements of continuous drilling under conditions of strong pressure changes and imbalance. Links for more information about the product: http://www.solidscontrolsystem.com/product-item/mud-gas-separator/