Drilling Mud Circulation System is composed of solids control equipment such as: shale shaker, vaccum degasser, desilter desander, decanter centrifuge, mud circulation tanks with agitators and mixing hopper, mud gas separator etc. Brightway is the Drilling Mud Circulation Equipment and Mud Circulation System designer and Manufacturer in China, and can design and manufacture drilling Mud Circulation System for oil gas drilling rig, such as: ZJ30 1000hp, ZJ40 1000hp, zj50 1500hp, ZJ70 2000hp, ZJ90 3000hp drilling rig.

Function of Drilling Mud Circulation System

Mud circulation system in oil & gas industries is also called drilling solids control system. It is widely used in the oil drilling industry, gas drilling industry, horizontal directional drilling, etc. With mud circulation system, it is now to solve the damage and impact of traditional operation on the environment.

The role of mud circulation system in oil & gas industries:

1. The mud circulation system in oil & gas is safe and convenient to operate, simple to maintain, and stable and reliable in operation.

2. Realize mud recycling and greatly reduce the cost of waste slurry transportation.

3. The recycled mud is very effective in reducing borehole accidents caused by unstable performance and ensure the smooth progress of the project.

4. The mud is fully recovered and purified, which can effectively control the performance indicators of the mud and improve economic benefits.

5. The mud circulation system in oil & gas is configured according to the amount of mud to be processed, which is generally composed of a shale shaker, a desander, a desilter, a mud cleaner, a funnel, a pump, a tank, a dosing device, a stirrer, etc.

6. The general process is that the drilling mud is processed by solids control equipment such as vibrating screen, de-sander, desilter, centrifuge, etc., and then sent back to drilling. If other ingredient is needed, then it is added to meet the requirements.

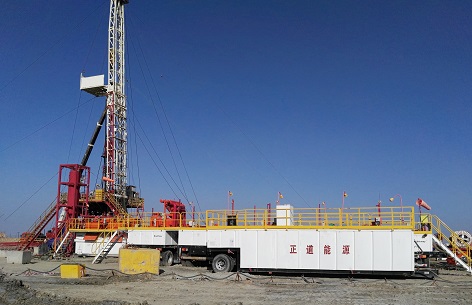

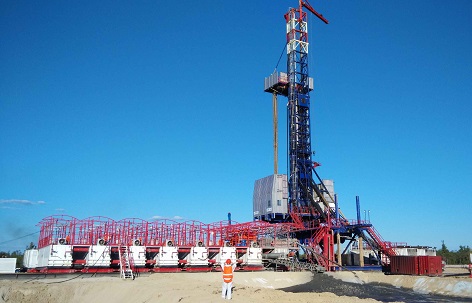

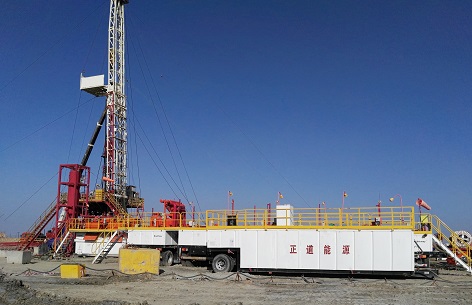

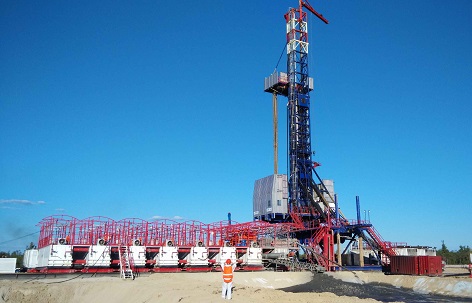

Design of Drilling Mud Circulation System

1. The drilling mud circulation system is designed for different drilling conditions. Some drilling areas, such as Russia, require a mud circulation system that can withstand the cold; such as the Middle East, where the temperature is very high, and the mud circulation system needs to be designed to withstand high temperatures. For example, for desert areas, the mud circulation system can be designed to prevent wind and sand erosion;

2. The layout of the drilling mud circulation system can also be designed according to the working conditions of the drilling site. For example, the drilling site is narrow and the mud circulation system can be lined up; the drilling site is open, the mud circulation system layout can be side by side + the line layout; the drilling site needs to be moved, and the mud circulation system can all be implemented side by side;

3. Drilling mud circulation system for different types of drilling rigs is also divided into 1000HP drilling rig mud circulation system, suitable for drilling rigs with a drilling depth of 4 kilometers; 1500HP drilling rig mud circulation system, suitable for drilling rigs with a drilling depth of 5 kilometers; 2000HP drilling rig mud circulation system, suitable for Drilling rig with drilling depth of 7 kilometers; mud circulation system of 3000HP drilling rig, suitable for drilling rig with drilling depth of 9 kilometers, etc.

Please Leave Your Request

If you haven’t found useful information about “Mud Circulation System” from this page, please fill below table for detailed inquiry.

or send the request to our Company Email: brightway@bwwell.com we will feedback at the soonest!