ZDY12000LD Drilling Rig

As a new technology in engineering field, underground directional drilling technology of coal mine has been widely used in borehole drilling in gas drainage, water hazard control, geological exploration and accurate drilling fields. ZDY12000LD directional drilling rig, mud pulse transmission MWD system,...

WhatsApp

Email

Solids Control Equipment

As a new technology in engineering field, underground directional drilling technology of coal mine has been widely used in borehole drilling in gas drainage, water hazard control, geological exploration and accurate drilling fields. ZDY12000LD directional drilling rig, mud pulse transmission MWD system, assorted drilling tools and combined directional drilling technique are developed to solve current technical limitation of direction drilling. The whole set of equipment appears significant advantages. These advantages include enlarged power, high borehole accident handing capacity and high wireless MWD accuracy. Meanwhile, less drilling cutting and small borehole curvature are expected to generate by combined directional drilling technique. The ZDY12000LD drilling rig have completed the ultra-long directional drilling along the coal seam with the main hole depth of 3353m in Baode coal mine, which has once again set a new world record of directional drilling in China.

Description of ZDY12000LD drilling rig

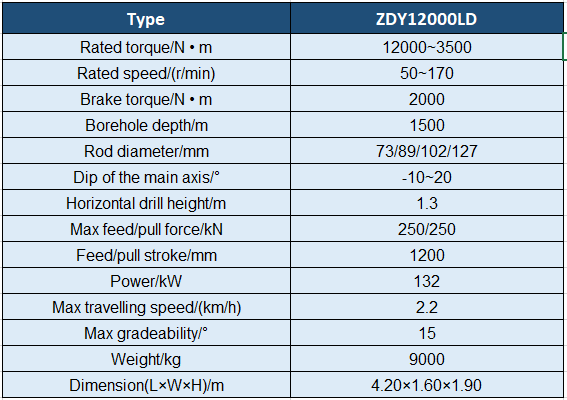

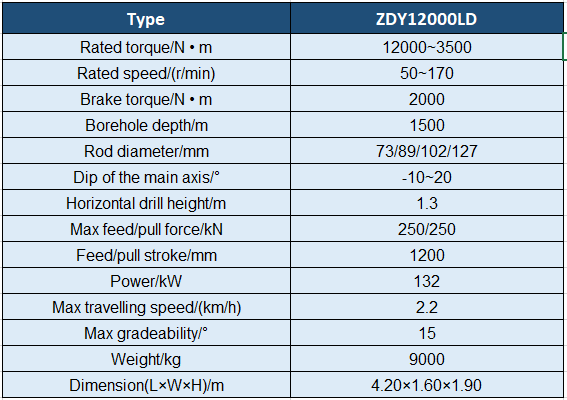

ZDY12000LD is a directional drilling rig with high rotary torque (the rated torque is 12000N.m), low rotary speed (range from 50r/m to 150r/m). The rig is capable for precise directional drilling operations with borehole depths of up to 1500m by using a downhole motor. It is suitable to drill large diameter underground borehole. The application of the rig includes directional drilling operations for gas drainage, water detection/drainage, grout injection, exploration of geological structure, detection of seam thickness, water injection in seam, etc. Technical parameters are listed in following table. The compact structure design of the rig makes it possible to effectively solve the problems of small output of the rig and inconvenient relocation. The design of large hole power head with double power input and planetary wheel deceleration realizes the adaptability of large output capacity and multi-process. The large opening compound gripper on the drilling rig can meet the needs of screwing and unloading drilling tools with large clamping force. The rig’s rubber cylinder hydraulic chucks support annular clearance self-compensation and efficient dynamic oil distribution. In addition, the drilling rig also has a friction braking device that meets the needs of directional drilling to hold the main shaft tightly, and a multi-support dual-cylinder direct-push attitude adjustment device that realizes convenient adjustment of opening parameters.

Parameter of ZDY12000LD drilling rig

Please Leave Your Request

If you haven’t found useful information about “ZDY12000LD drilling rig ” from this page, please fill below table for detailed inquiry.

or send the request to our Company Email: brightway@bwwell.com we will feedback at the soonest!