What are the vacuum degasser models used in oilfield drilling? What are the technical parameters of the vacuum degasser? How to select the vacuum degasser? This article will summarize the model, parameters and selection of vacuum degasser.

Model of BWZCQ Vacuum Degasser

The vacuum degasser is a secondary solids control device in the oilfield drilling process, and it plays an important role in restoring the specific gravity of the mud and stabilizing the viscosity of the mud.

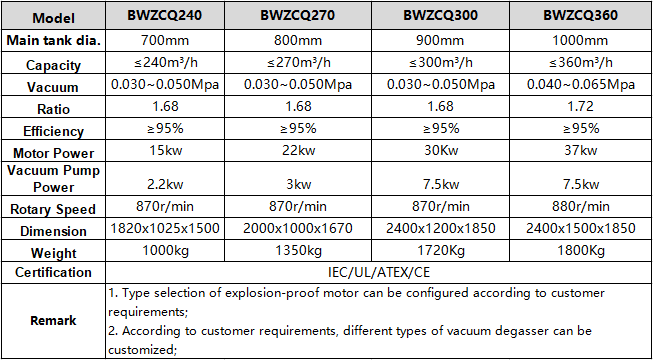

There are four conventional models of oilfield drilling fluid vacuum degasser: BWZCQ240, BWZCQ270, BWZCQ300, BWZCQ360, etc.

Each model represents a degasser with different processing efficiency. The larger of the model number, the higher of the degassing efficiency it represents. Generally, the selection of vacuum degasser is determined according to the different drilling depths of ZJ20-ZJ70.

Parameters of BWZCQ Vacuum Degasser

Selection of BWZCQ Vacuum Degasser

BWZCQ240 vacuum degasser: generally configured for use in the ZJ30 drilling rig solids control system. The degassing efficiency is about 240 cubic meters per hour.

BWZCQ270 vacuum degasser: Generally configured in the ZJ40-50 drilling rig solids control system, the degassing efficiency is about 270 cubic meters per hour.

BWZCQ360 vacuum degasser: the degassing efficiency is about 360 cubic meters per hour. Generally configured to the ZJ70 drilling rig solid control system for use.